Orange is the New Paper – The Story of the Crush Citrus Paper

Taken together, the family of shrubs and flowering trees known as citrus (orange, lemon, grapefruit, pomelo, and lime) sit firmly in the top 5 of global fruit production.

Widely popular around the world for their sweet-sour taste, most citrus fruits are generally peeled, split, and eaten fresh, or the fleshy pulp is extracted and drunk as a healthy and refreshing beverage.

Originally native to the subtropical and tropical regions of Asia, where they were first cultivated many centuries ago, they later spread to India, Africa, the Mediterranean, reaching much of the world by the 17th century.

Read More about : Paper Prototyping

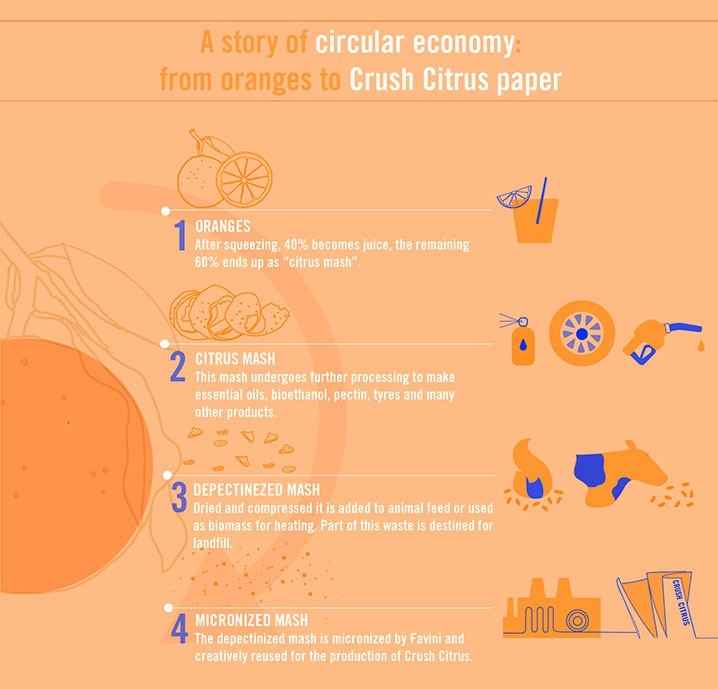

The orange fruit accounts for about 70% of all citrus production. Indeed, some 78 million metric tons of it was produced globally in 2019. The bulk of that amount is used to make juice extract, but careful analysis reveals that less than half the volume of the orange becomes juice, with the rest being discarded as citrus mash.

After the Juice Comes Paper

The citrus mash then undergoes further processing to give off essential oils, bioethanol, pectin, candied fruit, tires, etc.

The residue from these processes is known as “depectinized mash”. In general, this waste is dried, compressed, then added to animal feed or used as biomass for heating, but much of it is nonetheless destined for landfills that are a leading cause of greenhouse gases.

Read more about Paper Ginkgo Biloba

But with the increased awareness about the impact of human activities on the environment, people and corporations are now more than ever invested in cutting emissions and reducing their carbon footprint.

A Big win for Orange and Paper

Leading the push for an eco-friendlier production and utilization of agro-industrial waste is Favini, an Italy-based paper mill that has revolutionized the production of paper with its line of Crush Paper.

The depectinized mash, previously considered a material of little value, has found new importance in the favini process of recovering and creatively upcycling agro-allied waste. It is now a key raw material in the production of high-quality ecological papers, replacing up to 15% of tree cellulose, thereby converting an otherwise linear process into a circular one.

A Sweet Future for Paper

As frontline distributors of the Favini brand in North America and advocates of ecological sustainability in the production of paper, this article continues paperpapers series on Crush Paper with a focus on how it is manufactured.

Crush Citrus paper is applicable for several purposes, including luxury packaging, catalogs, brochures, stationery tags, cards, labels, brand collateral, notebooks, invitations, corporate identity suites: from folders, business cards, envelopes, and other creative projects.

The paper is also nearly 100% recyclable, and it is expected to continue to be reused in successive production cycles according to the concept of the circular economy model that seeks to conserve energy and natural resources.

More on Crush Paper

Crush is an eco-friendly range of papers by Favini, made by replacing up to 15% of virgin tree pulp with the process residues of organic products.

The Crush paper range includes by-products from barley, grapes, cherries, lavender, corn, olives, coffee, kiwi fruit, and almonds. These natural raw materials are saved from landfills and used to make these distinctive and vivid papers.

Click here to read more about Favini crush paper, the revolution in sustainable and eco-friendly manufacture of paper.

One Comment